What is mezzanine floor?

Mezzanine floor is the intermediate floor in the building built between ceiling and ground floor of the building to provide extra space. Mezzanines are versatile, semi-permanent structures and can serve various purposes, depending on the needs of the building or business. Mezzanine floors offer high flexibility and are very easy to expand without the need for extensive construction or relocation.

How to Build mezzanine floor? The construction of mezzanine floor needs careful planning and execution to ensure their stability, safety, and compliance with building regulations. Here are the key considerations in this process: –

Structural design: –

- Load Analysis: Determine the load-bearing requirements based on the intended use of the mezzanine (Weight of equipment, inventory, and occupants).

- Professional Design: Hire a structural engineer to design the mezzanine structure, including columns, beams, and flooring materials.

Material selection: –

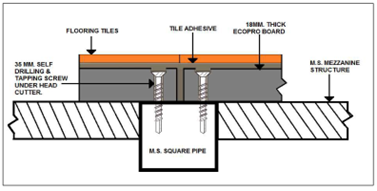

- Flooring: Choose CEMPLY18 Cement board for flooring. Cemply18 is high strength cement board resistant to fire, sound, termite and water.

- Support Structure: Select materials for columns, beams, and other structural elements, often using steel for its strength.

Safety consideration: –

- Include handrails, toe board, and safety gates to avoid falls or accident.

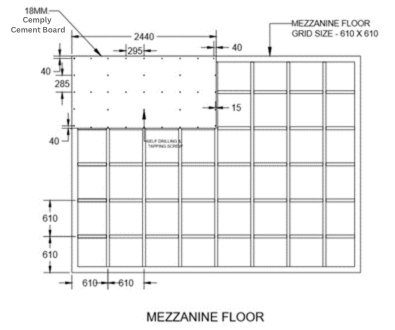

- Steel structure for mezzanine floor should be made as per the directions of the concerned structural engineer. Grid size of this structure should be 610 X 610mm for normal loads and 400 X 400mm or 300 X 300mm for heavy loads. In any case it should not be more than 610 X 610mm.

INSTALLATION:

MEZZANINE GRID SIZE: 610MM. X 610MM.

- Fix the 18mm Cemply cement board on the approved grid by drilling holes as per shown in fig.

- Keep a 2-3 mm gap between the edges of the boards.

- All structural member should be in line & level.

- It should be free from welding spatters.

- All the four edges of the board should be well supported.

- Joints should be staggered by half length of the board.

- A gap of 5mm is provided all around the mezzanine periphery between the board edge and the wall. Gap is filled with sealant. Cemply boards can be finished with different floor covering like carpet and Ceramic Tiles.

About Cemply 18 Cement Board:-

Cemply 18 cement boards are manufactured using the latest technology as per IS 2096. It is a mixture of cement, Pozzolanic Material, fibre, flyash and cotton rug pulp.

CEMPLY sheets are cured by the Autoclave (HTHP) process. In this process, the boards are subjected to high steam pressure and high temperatures of 1600 – 1800 C for a prolonged period of 14 hours. This curing process facilitates the formulation of hydrosilicates of high strength by reaction between lime and silica.

This unique curing process imparts a high degree of dimensional stability to the sheets. The reaction products from steam curing make boards tough and, at the same time easy to work with. Autoclaved sheets are more dimensionally stable, more strong and have more strength compared to non-autoclaved sheets.